3D printing facilities at the point of care in hospitals

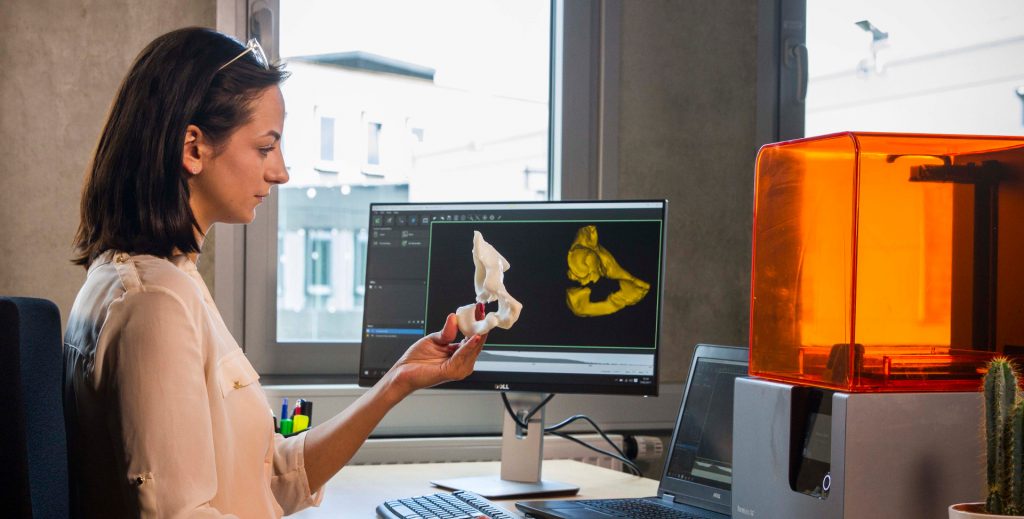

How to go from scanning to 3D model

Key benefits of 3D-printed anatomical models

Advance your complex procedure planning

Use anatomical models for diagnostic and preoperative planning to achieve desired patient outcomes.

Enrich multidisciplinary team communication

Create new group dynamics and improve cohesion within multidisciplinary teams by providing advanced visualization and 3D-printed models to stimulate procedural discussions.

Communicate more effectively with your patients

Build a deeper relationship with your patients and their families by helping them better understand the intended treatment procedure with 3D anatomical models.

Train with concrete anatomy

Encourage resident and medical students to learn by providing 3D models that allow them to more clearly visualize complex pathologies and perform procedures.

Key benefits of 3D-printed anatomical models

Congenital or Structural Heart Disease

Gain better insight into intracardiac morphology improving pre-procedural planning.

Complex trauma fractures

Get a better understanding of the broken path.

CMF

Start your CMF reconstructive and orthognathic cases with 3D printed CMF models and continue with digital planning.

Radiology

Expand radiology expertise by establishing a central point-of-care facility that provides 3D anatomical models across different departments.

Discover new features and tools

CLEAR CERTIFICATION OF MODELING RESULTS

With Mimics inPrint, store modeling results in your hospital’s PACS system, keep patient records up-to-date and avoid healthcare compliance concerns.

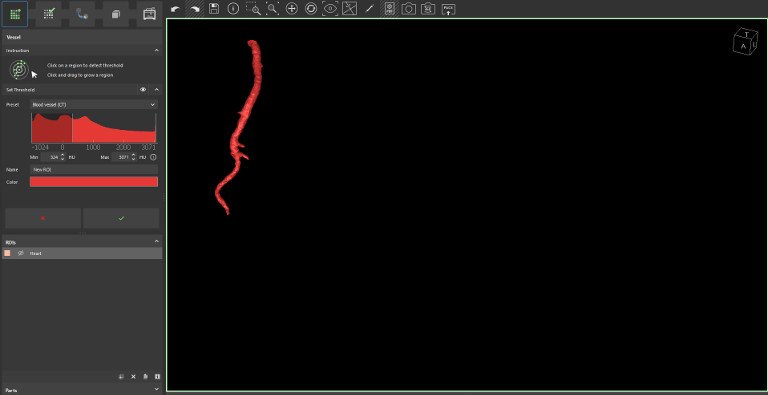

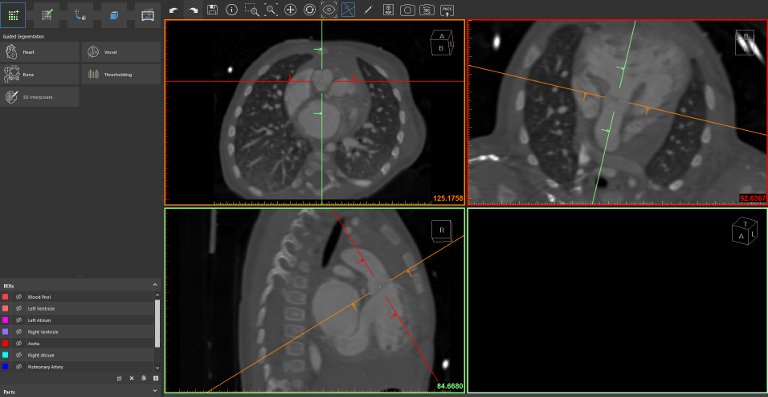

FASTER VASCULAR SEGMENTATION

Segment vascular anatomy faster with the new dedicated vessel segmentation tool in Mimics inPrint.

EFFECTIVE BONE FILLING

Print bone components fast and use media efficiently.

ENHANCED COMPATIBILITY WITHIN THE MATERIALISE SOFTWARE FAMILY

When modeling and designing your components, feel free to use the Materialize app that suits you best. Copy and paste your objects between Mimics inPrint and Mimics Innovation Suite.

ENHANCED CARDIAC MODELING

Perform multi-plane restyling (MPR) to support the planning and 3D modeling process.

DEEP INTEGRATION WITH SIEMENS SYNGO.VIA

If you are a Siemens Syngo.via customer, Mimics inPrint and OpenApps will facilitate deeper integration into your clinical routine.

START WITH IN-house 3D PRINTING

If you do not have access to a 3D printer, contact Materialize to discuss your situation. Materialize will thoroughly evaluate your request before choosing the most suitable printer for your model printing needs.

Materialize can support you with a customized solution to get you started.

OUTSOURCE YOUR 3D PRINTING

If you are in the process of evaluating your 3D printing needs or are only printing models in certain situations, you may prefer to work with an external service provider.

Materialize offers you the widest selection of printing technologies available in its medically approved printing factory.

USE PRINTERS CERTIFIED FOR DIAGNOSTIC USE

Along with a quality-controlled medical device software, your 3D lab needs certified printers and materials to derive clinical benefits from your 3D printing program. Bring hardware manufacturers and partners to life to validate a range of compatible printers and materials through extensive performance testing.

Materialize helps you get off to a good start with a verified installation and a secure environment.