Sterile Print Media

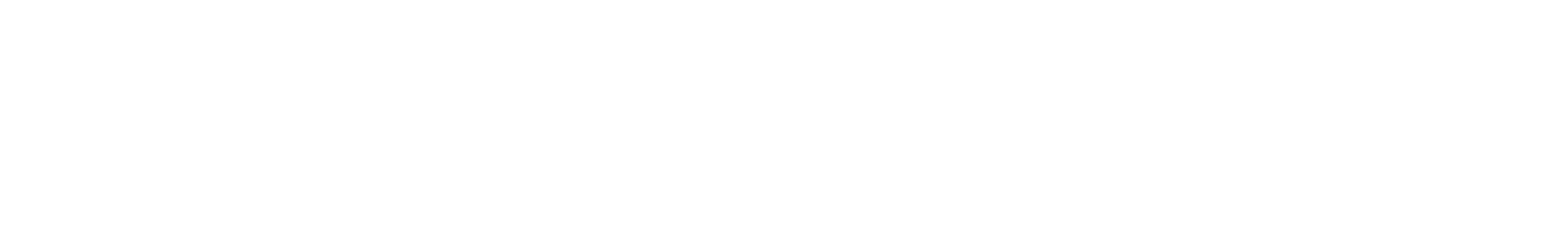

The hot air filter system analyzes the component geometry and adapts the heating power so that optimum energy input is always achieved. The airflow surrounding the component is filtered in a practically particle-free circuit.

New Extrusion Technology

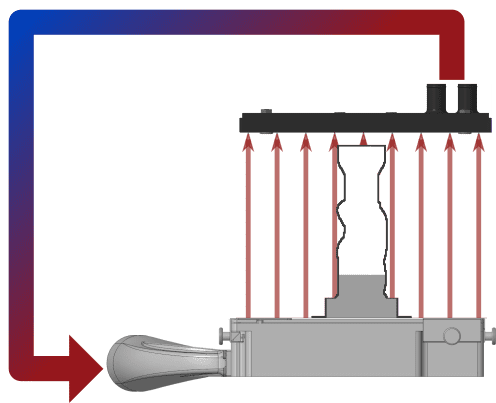

Our extruder has been developed with flexibility and durability in mind. Four times higher feed force than the previous model ensures a precise material flow. All components in contact with the printing material are made of biocompatible materials: PEEK, titanium, 316L steel and PTFE.

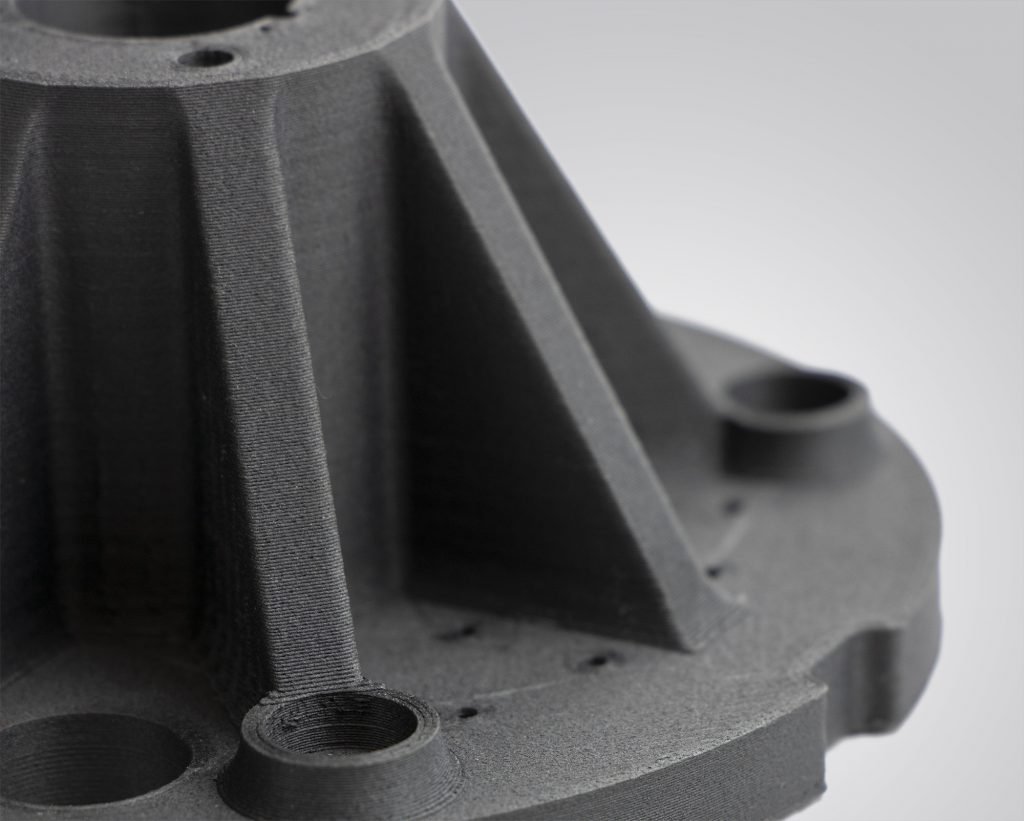

Biocompatible Filaments

In collaboration with Evonik, materials and filaments have been tested for their biocompatibility and the relevant tests have been successfully completed. In this way, it allows medical devices up to Class III to be produced from PEEK.

Traceable Print Process

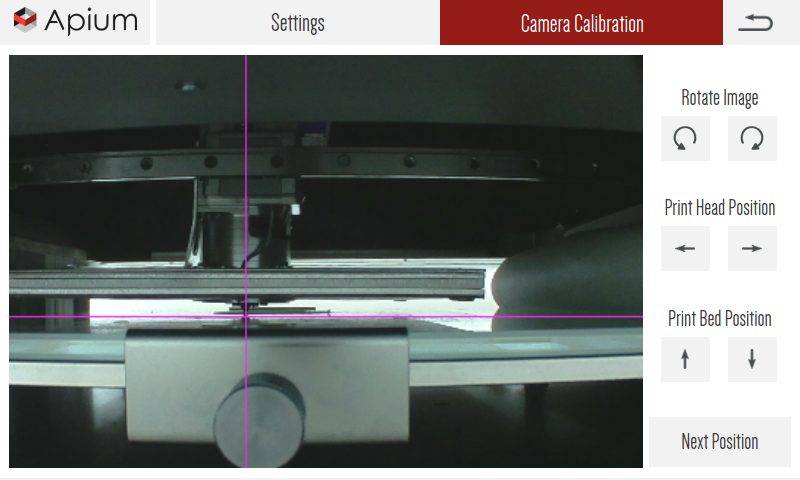

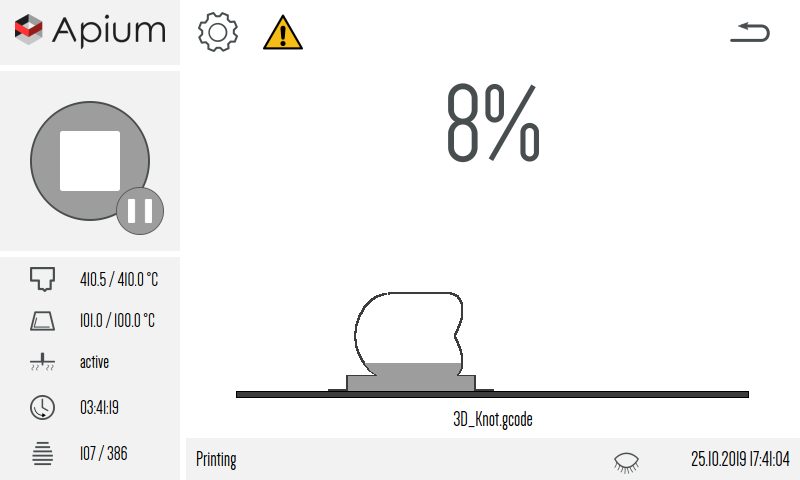

With the help of the camera system, temperature monitoring and servo motors are integrated, the printing process is continuously monitored. In this way, it allows the printer to intervene automatically when there are deviations during the process.

Reproducibility

Integrated calibration processes ensure consistent component quality. The software automatically informs about maintenance operations and guides you step-by-step through the process.

Documentation & Security

All important parameters for the printing process are automatically provided in a PDF protocol. System-integrated user management prevents unwanted access. For your data security, we have decided not to work with cloud-based methods.

Embedded Software

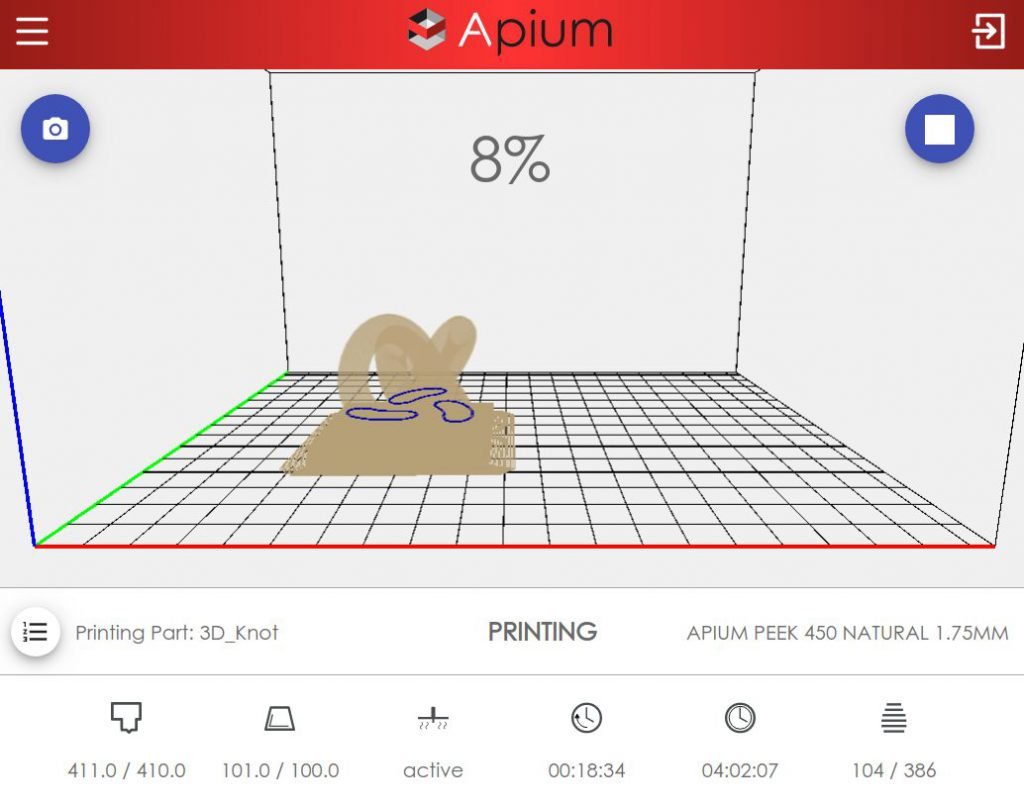

The system-integrated control software is adapted to our printer hardware and optimized for processing high-performance polymers. Its user-friendly interface makes the printer easy to use. You can always manage print jobs and check the status of the printer.

Technical support

Our service department will provide you with training on the use of your printer. We are happy to answer any questions you may have about printing and other challenges of 3D printing.

Print Size

130 x 130 x 120 mm

Printer Size

850 x 685 x 675 mm

Nozzle Diameter

0.2 – 0.8 mm

Layer Thickness

0.05 – 0.6 mm

Wall Thickness

> 250 µm

Printhead Temperature

up to 540°C

Hot Air Filter System

up to 280°C

Thrust Bed Material

Stainless steel 316L

Sound Quantity

< 70 dB(A)

Supported File Extensions

STL, OBJ, G-Kod

Life-Saving Innovation

We offer a unique opportunity to manufacture patient-specific prostheses and implants at low costs and with minimal lead times, without affecting the biocompatibility and sterilization properties of PEEK. In this way, the part meets the high requirements for in-vivo applications.

With the design freedom that comes with our technology, you can create complex geometries using radiological imaging data. You can produce a digital implant model produced from patient-specific data in a few hours with PEEK, and use it for patient treatment after sterilization.

The possibilities offered by Apium’s Medical PEEK 3D Printing Technology provide convenience in the treatment of craniomaxillofacial, hand and spine disorders where patient-specific solutions are most demanded. With Apium, you can save time, cost and personnel costs compared to traditional production methods. Apium enables a faster and more flexible reaction in emergency situations.

SOFTWARE IS THE STRENGTH OF APIUM

Software is one of Apium’s core competencies. Apium provides simple and efficient operation to the user with its interface on the printer’s touch surface. Service and maintenance functions facilitate daily use of the printer and provide detailed access to all settings. Its web interface applet and printer-integrated camera make it easy to monitor print processes and manage the printer over the network from a remote workplace.

FREQUENTLY ASKED QUESTIONS

Apium developed M220 Series 3D printers to develop and manufacture PEEK’s medical applications. As BTech, we will supply natural colored, high viscosity polyether ether ketone (PEEK) filament. This filament is specially designed for long-term implants.

Apium research and develop PEEK Filaments together with Evonik.

Learn more about medical grade PEEK filament, please contact BTech experts.

Apium M220 Series 3D printers ensure the preservation of biocompatibility and sterilization properties of printed medical products. Biocompatibility of medical grade PEEK Filament and 3D printed medical devices has been tested following ISO 10993 standards.

A summary of the biocompatibility test results is available upon request.

The use of Apium M220 Series 3D printers in medical product manufacturing is similar to other manufacturing technologies in the medical industry.

To better understand the entire procedure, please watch the video at the top of this section or fill out the form to download related articles.

BTech offers a unique solution to achieve high quality results with the additive manufacturing of PEEK medical products. To gain knowledge and skills about PEEK 3D printing, you can start your experiments with the P220 series machines before the delivery of your M220 machine. A customized and advanced training for your application area will be provided by our Service Center experts.

Throughout your additive manufacturing experience, BTech experts will support you every step of the way to successfully implement and operate Apium systems.

Apium M220 Series 3D printers are available directly from BTech which is one of Apium’s official distributors.

To get a quote, please contact our experts by filling out the “Request A Demo” form.

Medical grade PEEK Filament can be purchased directly from BTech. Please contact BTech experts to get a quote.