Bring Your Business to Life

The Allevi 3 bioprinter lets you print any cell line to any geometry for any application you can imagine. Allevi 3 has the versatility to more than meet your needs today and grow with your business.

Designed and optimized for:

- Biomedical Devices

- Bone and cartilage

- Dentistry

- Disease Modeling

- Drug Tests

- Electroactive tissue

- Heart Valves

- Biomedical Devices

- Biomedical Devices

- Microfluidics

- Biomedical Devices

- Organoids

- Organ on a chip

- Pharmaceutical Development

- Soft Tissues

- Tissue Engineering

- Thin Layers

- Regenerative Medicine

- Vascular System

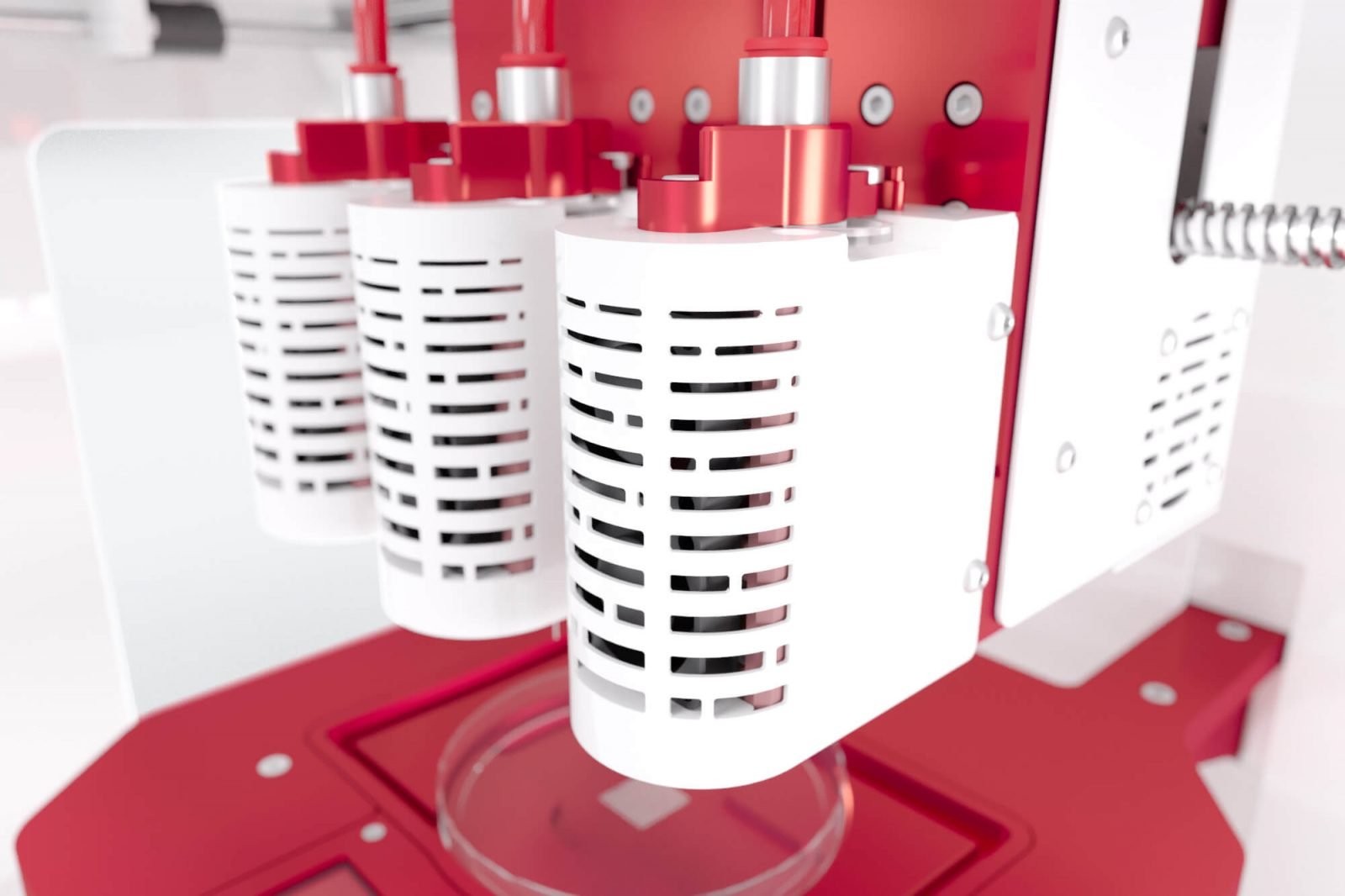

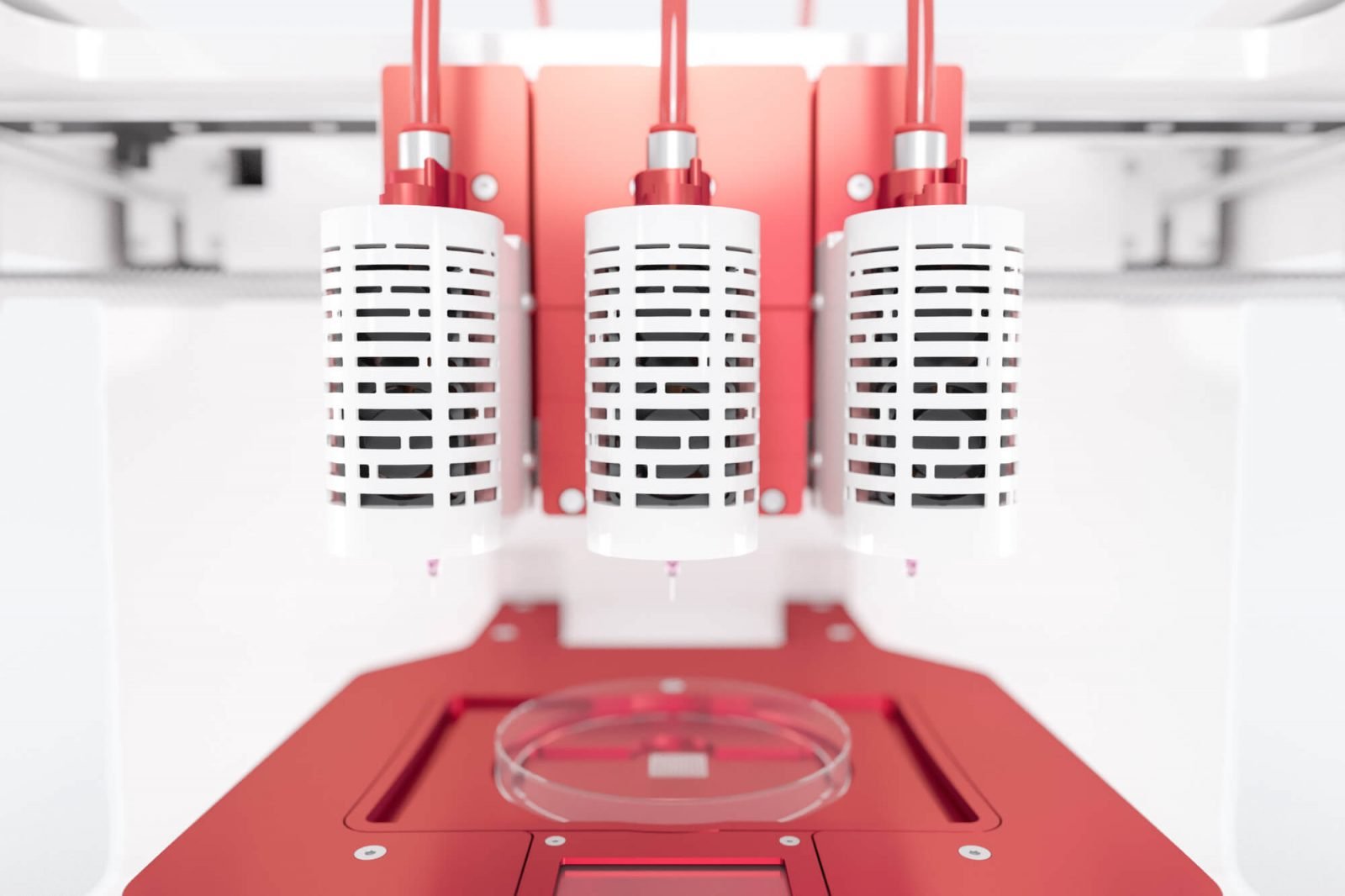

Three Extruder System

Print multicellular tissues easily and quickly with three extruders. Incorporate the vascular system into thick tissues, print supports for complex geometries, or combine thermoplastics with vascularized soft tissues. One-step fabrication makes it easy to create complex textures.

Heated Print Bed

The print bed has temperature control from room temperature to 60°C to keep cells alive for longer print sessions and is compatible with petri dishes, well plates and glass slides.

Allevi CORE Compatible

The Allevi 3,5 is designed for use with the Allevi CORE removable extruder system, which accepts 5 mL plastic or metal luer lock syringes and is optimized for all the bioinks we offer.

Auto Calibration

Gone are the days of manually calibrating your extruder before you start printing. Press Calibrate and let the Allevi 3 bioprinter do all the work.

Photo Cure

UV / Blue Light

The maker of curing biomaterials in visible or ultraviolet light with the Allevi 3 bioprinter. The extruder houses two separate LEDs, 365nm and 405nm.

Temperature Control

4˚ – 160˚ C

With temperature control from 4°C to 160°C, the Allevi 3 bioprinter can print a wide variety of bioinks, including collagen solutions, matrigel solutions, gelatin methacrylate, alginate, graphene, carbohydrate glass, polycaprolactone (PCL) and PLGA.

Pneumatic Extrusion

The Allevi 3 is built around a compressed air pneumatic system, making it very easy to achieve clean starts and stops in printing. Pressure ranges from 1 to 120 PSI accommodate a wide variety of viscous materials.

TECHNICIAL SPECIFICATIONS

| Extruders | 3 × Allevi CORE Extruder |

| Photocuring | LED – 365nm and 405nm |

| Printing Technology | Fused Deposition Manufacturing (FDM) |

| Compatible Syringes | 5 mL plastic, 5 mL metal |

| Min. Temp | 4˚ C |

| Max. Temp | 160˚ C |

| Min. Pressure | 1 PSI |

| Max. Pressure | 120 PSI |

| Pressure Variance | ±1 PSI |

| Heated Bed Temperature | Ambient – 60˚ C |

| Construction | Aluminum Frame |

| X, Y Precision | 1 μm |

| Z Precision | 1 μm |

| Build Volume (W × H × D) | 3.5 × 2.4 × 5.1 in (42.8 in³) |

| Build Volume Metric (W × H × D) | 9 × 6 × 13 cm (702 cm³) |

| Supported Build Plates | Slide, Petri Dish, Well Plate |

| Dimensions (W × H × D) | 18.4 × 15.2 × 14.2 in |

| Dimensions Metric (W × H × D) | 46.7 × 38.8 × 36.0 cm |

| Weight | 48 lbs (21.8 kg) |

| Power Requirements | AC 110V – 220V |